| No. | Items | Parameters |

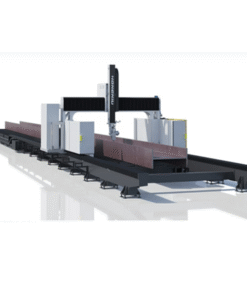

| 1 | Effective cutting width | 5150 mm |

| 2 | Effective cutting length | 26000 mm |

| 3 | Flame cutting thickness | 6-150 mm |

| 4 | Plasma cutting thickness | Up to plasma power source |

| 5 | Cutting torch lifting distance | 200 mm |

| 6 | Operating speed of whole machine | 0-9000 mm/min |

| 7 | Setting speed error | ≤±5% |

| 8 | Automatically adjust high precision | ≤±1.0mm |

| 9 | Longitudinal straight line accuracy | ±0.3mm |

| 10 | Overall accuracy of whole machine (According to the right graphics) side length (four sides) 1000X1000 Scribing speed 500-800mm/min |

|

| 11 | Side length (four sides) | ±0.5mm |

| 12 | Diagonal error|AD-BC| | ±0.5mm |

| 13 | Back to origin deviation | ±0.2mm |

| 14 | Intersection deviation | ±0.5mm |

| 15 | Forward and reverse straight line deviation |

±0.2mm |

| 16 | Cutting surface quality (roughness) (select δ=25 plate) |

Rz(um)=70+1.2a Roughness 12.5 |

| 17 | Perpendicularity and slope tolerance | μ(mm)=0.4+0.015a Tool: Angle ruler |

| 18 | Straight angle | Diagonal error≦ ±0.2 mm |

| 19 | Unevenness of walking | longitudinal≦ ±0.2mm/effective length Horizontal≦ ±0.2mm/effective length |

| 20 | Torch angle error | ≦ ±0.5º |

| 21 | Equipment noise | ≤80decibel |

| 22 | Package size | 4300x1900x1700 14CBM 1700KGS Wooden case or 20 feet container |