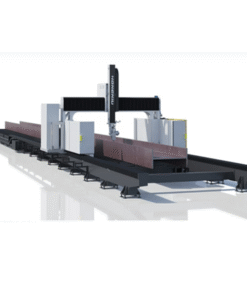

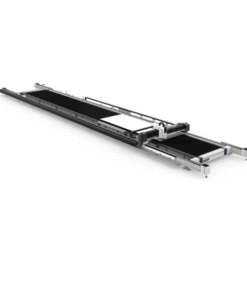

| 1 | Holding diameter range | φ200~φ2200mm |

| 2 | The torch traverse(X) | 12000mm |

| 3 | Chuck hole diameter(max) | φ90mm |

| 4 | Intersecting line numerical control system | Australia FastPBC |

| 5 | Control axle number | 5 +1 axis |

| 6 | Flame cutting device | And plasma exchange 1 sets |

| 7 | Flame cutting thickness | 6-80mm |

| 8 | FFlame beveling thickness | 6-80mm |

| 9 | Plasma cutting device | Plasma 1 set |

| 10 | Plasma cutting thickness | 1-50mm |

| 11 | PPlasma beveling thickness | 1-30mm |

| 12 | A Workpiece rotation speed | 0~37.5r/min |

| 13 | X axis velocity | 12000mm/min |

| 14 | Maximum travel of Z axis (upper, lower) | 620mm |

| 15 | Z axis velocity | 1500mm/min |

| 16 | WX The torch swing along the X axis direction of maximum rotation angle |

±45° |

| 17 | WX axis velocity | 75r/min |

| 18 | WY The torch swing along the X axis direction of maximum rotation angle |

±45° |

| 19 | WY axis velocity | 75r/min |

| 20 | Profile tracking shaft | ±15mm |

| 21 | Total equipment power | (without plasma power) 5KW |